The Challenge and Opportunity of Deep Geothermal Energy

As the world seeks sustainable energy solutions, deep geothermal resources represent a vast and largely untapped source of clean power. Hot Dry Rock (HDR) projects, which involve extracting heat from deep within the Earth, are at the forefront of this energy revolution. However, developing these resources presents significant technical challenges. Understanding the subsurface geology and tracking the effects of engineering activities like hydraulic fracturing are crucial for success. This is where microseismic monitoring technology becomes indispensable. By “listening” to the faint seismic signals generated deep underground, we can visualize fracture development in real-time, mitigate risks, and optimize the entire extraction process. As a leading provider of intelligent seismic sensors, SmartSolo offers the cutting-edge tools needed to meet these challenges head-on.

Jiangsu Hot Dry Rock Project Overview

Project Background and Objectives

In Jiangsu, China, a pioneering project was initiated to develop a carbonate-type Hot Dry Rock geothermal resource. The project involved drilling a well to a depth of 4,700 meters, with hydraulic fracturing operations conducted between 4,500 and 4,700 meters to enhance the permeability of the rock. The primary goal was to effectively stimulate the deep geothermal reservoir to enable efficient heat extraction. Success depends on accurately understanding the geometry and extent of the fractures created during stimulation.

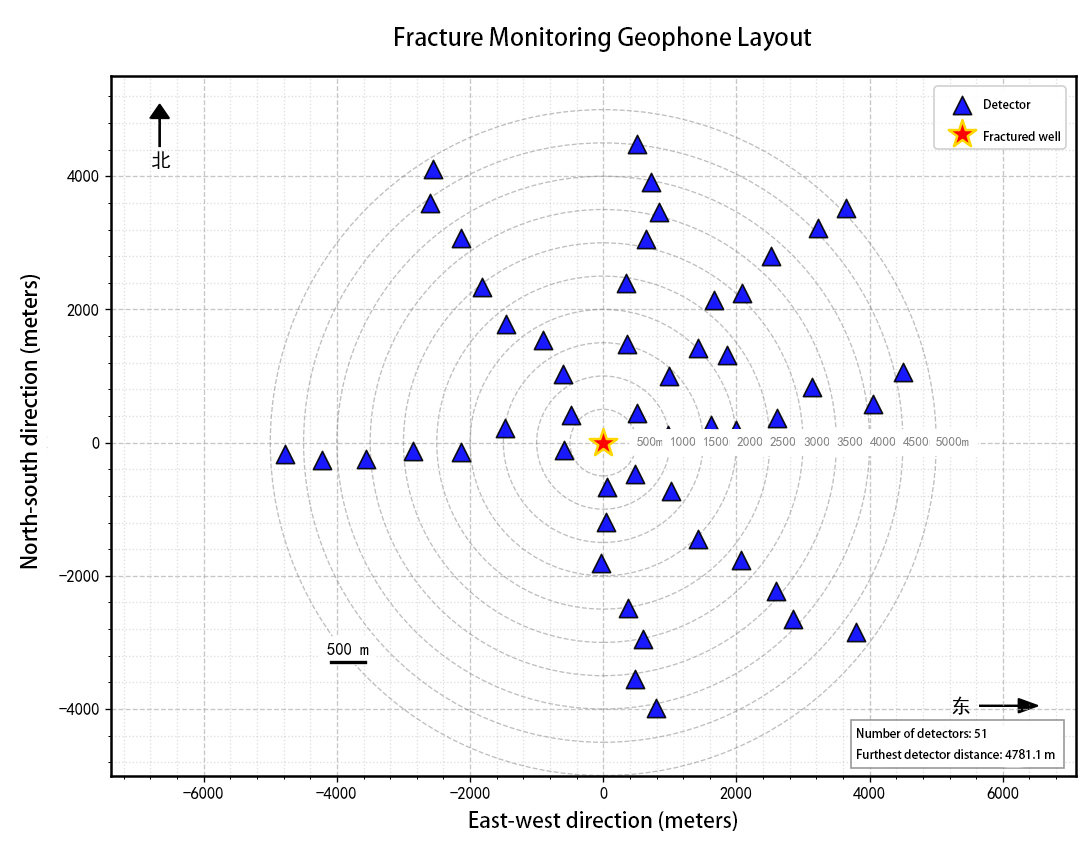

Advanced Observation System Deployment

To achieve precise monitoring, a comprehensive surface observation network was designed. A total of 51 single-component SmartSolo IGU-16HR 5Hz seismic nodes were deployed. These sensors were arranged in seven survey lines forming a star-shaped pattern that covered a 5-kilometer radius around the wellhead. The deployment was meticulously planned, with the nearest sensor located approximately 600 meters from the wellhead and the farthest at about 4,900 meters. The spacing between adjacent measurement points was maintained between 600 and 800 meters. This strategic layout ensured dense, high-quality data coverage of the entire target area, laying the foundation for successful microseismic monitoring.

The Critical Role of Microseismic Monitoring

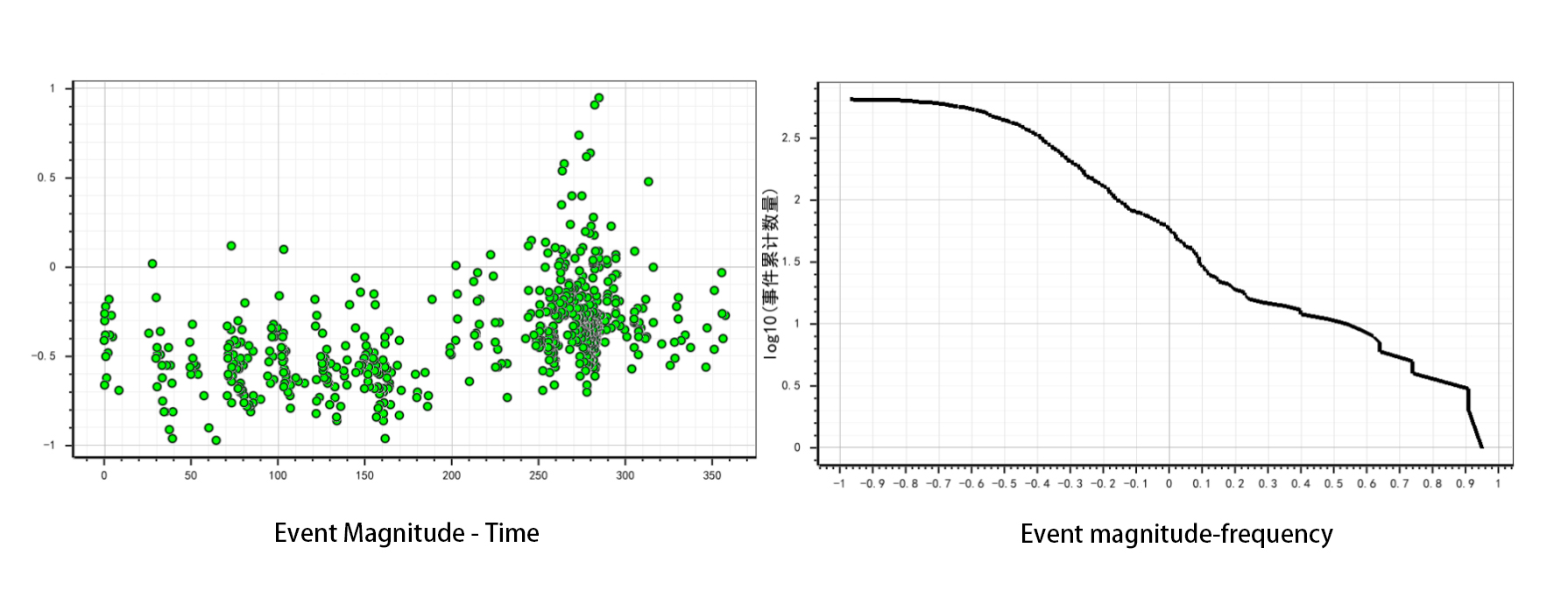

Real-Time Monitoring and Fracture Analysis

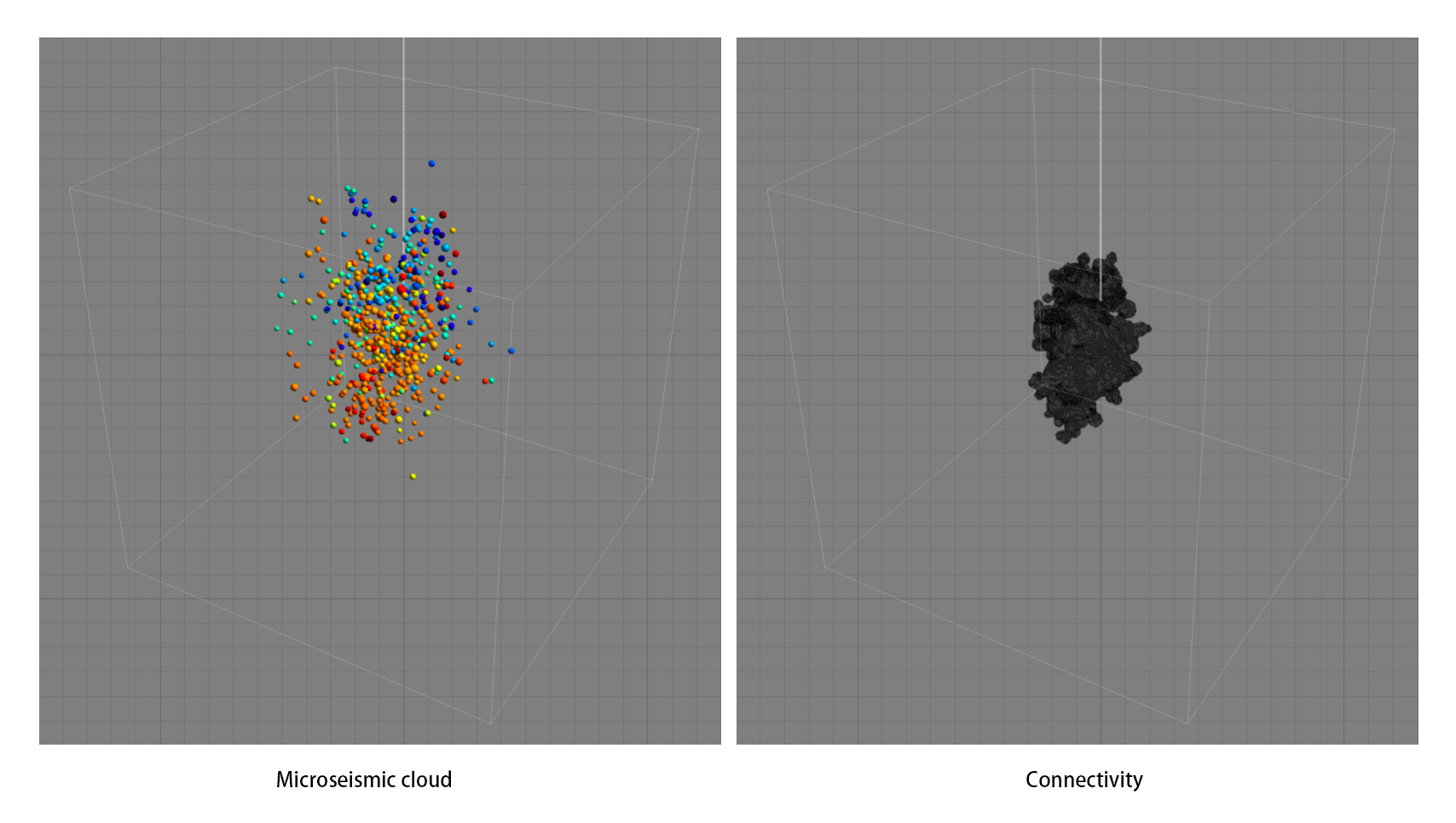

Microseismic monitoring is a passive seismic technique that records very small-scale earthquakes, or microseismic events, induced by industrial operations. In the Jiangsu project, the SmartSolo microseismic monitoring system was used to capture the weak seismic waves generated by the hydraulic fracturing process. By analyzing these signals, engineers can map the extent and behavior of the fracture network created deep within the earth. Over the course of two fracturing stages, the system identified more than 600 effective microseismic events, with the smallest having a magnitude of approximately -0.75. This data was used to generate a “microseismic cloud”, a 3D visualization that clearly depicted the location, growth, and orientation of the fractures, providing invaluable insights into the reservoir’s response to stimulation.

Optimizing Production and Guiding Decisions

The data from microseismic monitoring served as more than just a diagnostic tool; it was a guide for strategic decision-making. The detailed fracture maps allowed engineers to assess the effectiveness of the stimulation and make real-time adjustments to optimize the process. One of the most significant outcomes was the ability to provide a confident recommendation for the location of the production well. Remarkably, the production well location suggested by the surface-based SmartSolo monitoring system was identical to the location determined by traditional deep-well monitoring methods. This validated the accuracy and reliability of the surface monitoring approach, proving it to be a highly effective and efficient alternative for guiding geothermal development.

The SmartSolo Technology Advantages

Intelligent Nodes for High-Precision Monitoring

The success of the Jiangsu project was underpinned by the superior capabilities of the SmartSolo seismic nodes. The IGU-16HR is an intelligent seismic sensor known for its high sensitivity, precision, and reliability in demanding field conditions. Its lightweight, compact, and all-in-one design makes it easy to deploy, even in complex terrains, which significantly streamlines field operations for large-scale, high-density seismic surveys. The durability of SmartSolo nodes ensures they perform flawlessly throughout the project, capturing high-fidelity data that is essential for accurate microseismic analysis.

Global Applications and Proven Expertise

The technology from SmartSolo is trusted by researchers and industries worldwide for a wide range of applications beyond geothermal exploration. From urban fault detection and landslide monitoring to enhancing safety in gold mines, SmartSolo provides versatile and powerful solutions. This extensive experience across different geological settings and project scales demonstrates the robustness and adaptability of the technology. With the commitment to innovation and customer support, SmartSolo empowers its partners to tackle the most complex geophysical challenges and achieve their objectives with confidence.

Empowering the Future of Geothermal Exploration

The Jiangsu Hot Dry Rock project is a compelling example of how advanced microseismic monitoring technology can overcome the challenges of deep geothermal energy development. By providing a clear window into the subsurface, the SmartSolo system enables engineers to precisely map fracture networks, optimize stimulation, and make critical decisions with confidence. As the world continues to transition toward a clean energy future, the role of innovative geophysical tools will surely grow bigger. SmartSolo remains dedicated to pushing the boundaries of seismic technology, providing reliable, high-performance solutions needed to unlock the Earth’s secrets and power a sustainable future.